“The pressure of the drought pushes up feed costs everywhere”

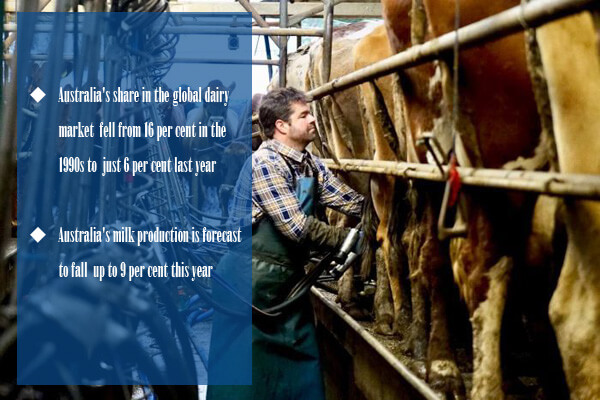

2019 was a tough year for Australian Dairy Industry. Water allocations, high input feed costs, and inconsistent milk prices, has lead to the struggles and hardship of Australia's dairy farmers. In 2019, there are fewer than 6,000 dairy farms in Australia, the figure would be even smaller in the coming year.

Skyrocketing irrigation water and feed costs hit not only dairy farmers’ profits but their confidence, in these real struggles and low confidence, people pull back on investment, which, to some extent, will make the dairy industry/crisis even more worse in 2020.

The downfall of large corporations that once dominated and dictated the market, foreign ownership making up a relatively significant share (77%) of Australia’s dairy processing has lead to Australian owned processors becoming the lifeline of the Dairy industry.

“How can we help? Making sure we use Australian produce wherever relevant and possible!”

Martin Buggy, the co-founder of Bondi Chai, calls on Australian consumers buy direct from Australian dairies to help the Australia’s dairy farming industry. Only broad community support can save the industry.

“How to self-help?”

We all know that, the future market competition would be the competition of higher quality, and therefore Australian owned dairy processors should reply on higher milk quality to hold on its market share, when competing with foreign ownership.

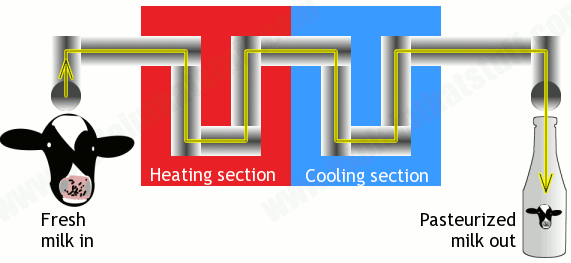

When it comes to milk quality, Pasteurization and Refrigeration would be the two main factors influencing milk safety that we have to mention.

“Pasteurization is most important in all dairy processing”

Why Pasteurization?

Pasteurizing the milk kills many harmful bacteria.

1.) to destroy disease causing microorganisms that may be present in milk.

2.) to destroy enzymes and spoilage microorganisms.

“Pasteurized milk must be stored under refrigeration”

Not only for end-consumers, but for distribution companies, refrigeration’s essential to keep milk and other dairy products fresh -- expensive but worth it.

For the dairy plant or the producer, pesteurized milk is normally required to have a shelf life, under refrigeration. Refrigeration helps to retard bacterial development, thus ensuring that the producer gets a better price for his milk. Pasteurization and refrigeration together make milk safe.

For distribution companies, they pick up milk in refrigerated milk trucks from the dairy plants or producers, and then transport the milk to grocery stores, schools, convenience markets and other retail outlets. Most refrigeration units installed on delivery van and trucks today have technology built in that can show the temperature within the truck body. Besides, the

transport refrigeration units can send the temperature results to the fleet management platform with GPS positioning. Such an advanced technology, should be introduced to Australian owned dairy plants or producers, to better monitor for problems at pickup and delivery, and to ensure purity and safety of the milk.

“How to choose suitable chiller unit to fit with refrigerated milk truck?”

Transport chiller units provide heat removal for trucks, trailers and vans. When it comes to selecting a chiller unit for milk truck, we should know that the truck’s width, height and length should influence the choice of your refrigeration unit; If it is undersized, the truck chiller will not cool properly; When properly sized, the refrigeration unit will increases production accuracy and reduces related costs; If it is oversized, it will be inefficient due to excessive cycling. All in all, more powerful chiller units are needed for larger milk trucks with more internal space and vice versa.

At

Guchen Thermo, we manufacture and supply 2 types of chiller units for pickup trucks and Ute. The main parameters of each type of system is listed below with links to more detailed information on their features, applications and technical data:

| Model |

C-200 |

C-300 |

| Compressor |

DY5H11/108cc |

DY5H14/138cc |

| Application |

For 2-10m³trucks |

For 10-15m³trucks |

| Driven Type |

Vehicle engine driven |

Vehicle engine driven |

| Installation |

Split front mounted |

Split front mounted |

Guchen Thermo

C-200 Chiller Unit for 2-10m³Trucks:

It is an air-cooled system with smaller footprints and easy monitoring/control. Its cooling capacity is 5,800BTU ( 0℃/32℉ ), enough for 10m³truck box.

Guchen Thermo

C-300 Chiller Unit for 10-15m³Trucks:

It is a compact and configurable refrigeration solution that are direct drive systems. It reduces the added cost of a secondary diesel engine. C-300 unit ensures the milk are at the correct temperature during transport, with cooling capacity 9,200BTU.