The Five Different Types of Transport Refrigeration Systems

At present, there are five types of refrigeration systems widely used in road transport refrigeration, which includes

The five types of refrigeration systems have many differences. To help you better understand every system,

Guchen Thermo has broken down each one in some summaries below.

Chilled-water refrigeration

At atmospheric pressure, the melting point of ice is 0℃. If the temperature below 0 degree Celsius is required, then the mixture of ice and salt is used. Salt lowers the melting point of water, which means that the more salt being added in the ice water within a certain range, the lower the melting point would be. It was proved that when you add salt whose quality equals to 29% of that of the ice water to the ice water, the melting temperature of the ice will be lowered down to the lowest value of -21.2℃.

In refrigerated transport, ice water with different salt content is selected in accordance with the required temperature of the refrigerated goods. For example, using salt ice water with a salt content of 22%, the temperature in the compartment can be maintained at -18℃ to -13℃.

Benefits: Chilled-water refrigeration system has low investment and low operating cost.

Drawbacks: Ice water is with relatively smaller latent heat absorption compared with the rest, therefore chilled-water refrigeration system has limited effect on the cooling of vehicle compartment. In addition, the mixture of salt and ice will pollute the environment/refrigerated food, corrode the carriage and damp the cargo.

Conclusion: chilled-water refrigeration system is mainly used for refrigerated transportation of fish and other aquatic products.

Dry Ice Refrigeration

Benefits: Dry ice refrigeration system is with low operating cost, simple design, and convenient to use. The low temperature and direct sublimation to a gas makes dry ice an effective refrigeration system.

When compared with chilled-water refrigeration, it can not only obtain a lower temperature, but also a larger cooling capacity. Therefore, the dry ice refrigeration method is suitable for frozen food transportation.

Drawbacks: The CO2 gas produced by the sublimation of dry ice can inhibit the reproduction of microorganisms, slow down the oxidation of fat and weaken the respiration of fruits and vegetables.

However, dry ice sublimation can easily cause frosting; too much CO2 gas will cause breathing difficulties and necrosis of refrigerated goods such as fruits and vegetables;

Besides, the temperature in the compartment is difficult to adjust; the cost of dry ice is high and the consumption is large, so it is less practical.

Cold Plate Refrigeration

Before transporting the goods, cold plates are pre-chilled, to make the refrigerant freeze. During refrigerated products transportation, the chilled refrigerant in the cold plates melt and absorb heat from the environment, thus keeping commodities at proper temperatures.

Structurally, cold plate refrigeration system is divided into integral type and split type.

In integral system, the power unit, cold plates and refrigeration unit are all placed on the refrigerated vehicle.

In split system, there is only refrigeration unit and cold plates. When parking, the power system drives the refrigeration unit to freeze the cold plates.

The commonly-used refrigerant is salt brine/eutectic solution whose melting point is usually about 10℃ lower than the temperature in the compartment. The components of the eutectic solution should be changed according to the desired temperature of transported goods.

Disadvantage: The cold plate device itself is heavy and large in size, occupying a certain volume of the carriage. And the traditional cold plate systems hold the body’s temperature during daily delivery runs of 8-15 hours.

Conclusion: cold plate refrigeration method is best suitable for short- to medium-distance refrigerated transportation in light or medium trucks.

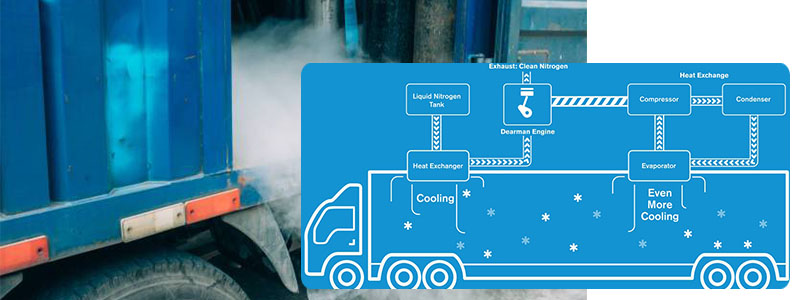

Liquid Nitrogen Refrigeration

The system is to use liquid nitrogen vaporization to absorb heat from the compartment, to cryogenically chill food. Under atmospheric pressure, the boiling point of liquid nitrogen is -196℃, and the latent heat of vaporization is 200kj/kg. The specific heat of nitrogen is 1.05J/g K. When every kilogram of liquid nitrogen is vaporized and heated to -20℃, the absorbed heat is about 358kj. Liquid nitrogen has a low boiling point and is a by-product of oxygen production, so it has been widely used.

The liquid nitrogen refrigeration device has a simple structure, reliable operation, no noise and pollution; liquid nitrogen has a large refrigeration capacity, rapid refrigeration, and is suitable for quick freezing. Liquid nitrogen vaporization will not make the compartment damp, and nitrogen is good for keeping food fresh. In addition, liquid nitrogen refrigeration has precise temperature control (+/-2℃). However, the cost of liquid nitrogen is high, and it needs to be charged frequently, so its promotion is subject to certain restrictions.

Mechanical Compression Refrigeration System

Due to factors such as transport distance & time, supporting facility and running cost, mechanical refrigeration is the most widely used refrigeration cycle method among all the 5 different types of

road transport refrigeration systems.

The main reason for the widespread use of mechanical refrigeration equipment is that the refrigeration unit can provide great refrigeration performance and with heating option, which significantly extends the application scope.

Compartment temperatures can be automatically and accurately adjusted. Taking

truck reefer units for example, its temperature range is +30℃ to -30℃ which can be used for various refrigerated goods transportation.

Although mechanical refrigeration systems are with relatively complicated structures and high purchase/operation costs, it is still the most reliable and effective refrigeration method used in worldwide

cold chain industry.