What’s the plan to save fuel from the refrigeration systems? Both the manufacturers and users are looking at ways to conserve it. The designers of a refrigeration unit make every endeavor to minimize the overall fuel consumption of a refrigerated delivery truck, especially the large ones installed with

direct drive truck freezer units. For truck units powered directly from the vehicle engine, electric standby refrigeration technology has been widely used in refrigerated transport. Electric standby power technology is not new, but it does is the fuel saver for refrigerated delivery.

What is Electric Standby Refrigeration Technology?

Such system is also called plug-in electric standby. It uses an external electric source enabling the refrigeration system to operate normally when the vehicle diesel engine shuts off. It works with an additional electric compressor to pump refrigerant gas through the TRU (transport refrigeration unit) when the vehicle engine is off.

The electric standby system is designed

1)to maintain the internal temperature of the refrigerated vehicle during idling (unloading);

2)to pre-cool the trailer to loading, thus minimizing vehicle energy use while start-up ;

3)to make sure that the power delivered to the truck unit is constant during extended stops.

An electric standby system is optional when it’s not required by customers. Guchen units have always included an electric standby feature, for example our

TR Series electric standby refrigeration unit

Electric standby is not new. Thermo King has offered such technology for reefers for 50 years, Guchen Thermo for more than 20 years. We are now being able to offer two responsible and efficient fuel-saving solutions for users:

a.Split electric standby system

b.Integrated electric standby system

In Guchen electric standby technology, a separate electric motor and compressor are used to allow the reefer to operate with AC220V, one phase, 50HZ, or AC380V, three phase, 50HZ.

Shore power on the refrigerated truck allows the truck unit to continue running when the vehicle switched off. It eliminates the need to operate the diesel engine powered refrigeration unit, thereby saves expense in the form of the diesel fuel needed to run the unit while the vehicle is staging. For trucking companies in Europe where fuel costs are much higher, the plug-in electric standby technology is considered as the best way to save cost because electric operation results in less diesel fuel consumption.

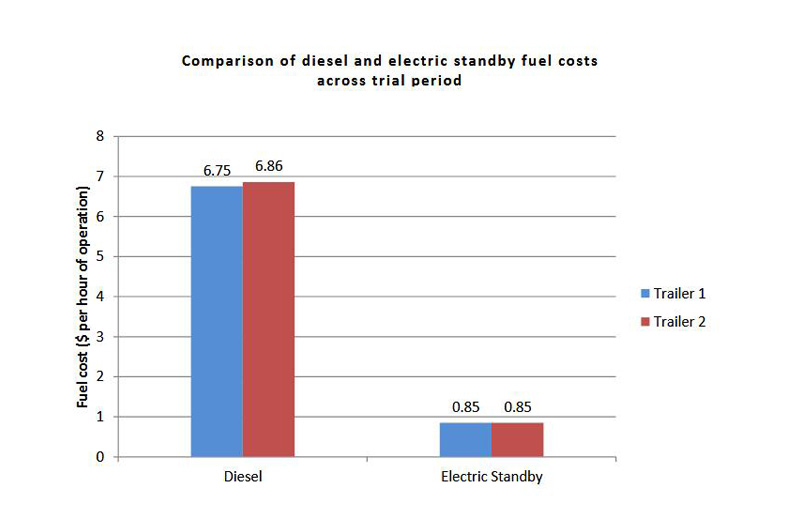

Lower cost of electricity vs diesel

Guchen optional electrical standby refrigeration systems provide 100% of the rated refrigeration capacity when the truck unit is plugged into AC220V / 380V power, which can save 40%-70%. this option is available for both small truck body and larger refrigerated trailers, best suited for applications that require freezing the cargo even when the refrigerated vehicle is stationary.

It was reported that a food service company in Canada saved almost $85,000 in fuel costs in the first year of using electric standby system in its 27 trailers. The company is not alone in realizing the economic benefits of operating electric standby units. In humid and hot Southeast United States, for a transportation company with approximately 250 refrigerated trailers that are all equipped with electric standby system, it was estimated that they can save as much as $20,000 per week by plugging the trailers in when they are parked. In Europe, such technology has been available for many years.

Truck refrigeration unit is plugged into the electric grid.

Another advantage is quite running. Refrigerated deliveries often occur during the late evening and early morning hours. The truck units are silent when plugged in, which is easier for drivers to sleep (overnight storage), solves refrigerated trucks idling problem (extended delivery routs) and to a great extend, reduces noise pollution generated by the on/off cycling of the diesel engines in abutting residential areas (unexpected schedule changes or local operations whose trailers and trucks return home every night).

Additionally, a primarily diesel-driven transport refrigeration unit with electric plug-in capability while parked helps to reduce operating costs as the diesel engine runs less, thereby prolonging the service life of the refrigeration unit.

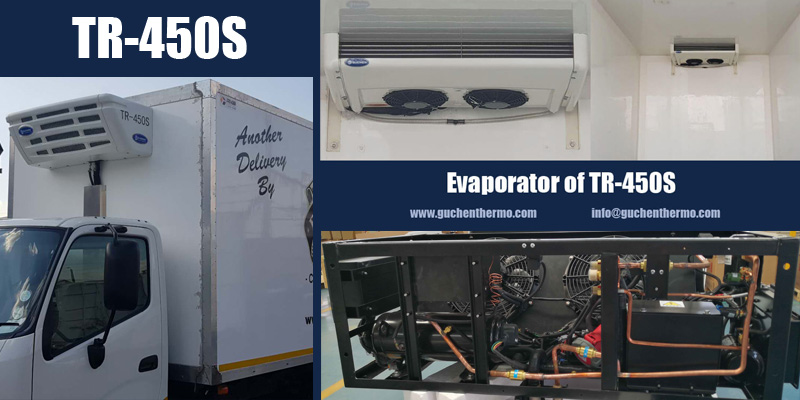

If you are transport refrigeration system distributor/ dealer, refrigerated truck bodies factory/manufacturer, food company, ice cream/milk/medicine company, Guchen Thermo can offer you complete refrigeration solution for your vehicles. All high-grade products like TR-200, TR-300, TR-350, TR-450, TR-550 (Click here to see more details on

diesel powered truck refrigeration units), are with

integrated electric standby (the corresponding models being TR-200S, TR-300S, TR-350S, TR-450S, TR-550S etc.) and

heating options.

More details relating to Guchen Thermo integrated electric standby refrigeration unit:

The system uses 220V one phase or 380V three phase.

It is more simple to install, and with lower failure rate, when compared with split electric standby system. Besides that, the standby system is integrated in the front mounted condensing unit, thus less chances of refrigerant leaks. The integrated electric standby unit is absolutely an efficient and reliable system that all users can trust on.