Models:

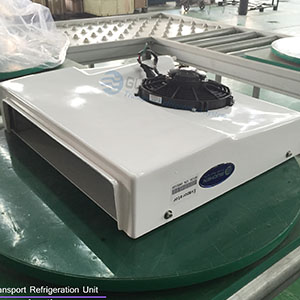

A truck refrigeration unit, also known as a transport refrigeration unit (TRU) or refrigeration unit, is a cooling or refrigeration unit mounted on a truck or trailer, usually powered by a separate diesel engine or electric motor that drives a compressor to circulate the refrigerant and generate cooling.

The main function of the truck refrigeration unit is to provide a low-temperature refrigeration environment for perishable goods or items that need to be stored in a low-temperature environment during transportation. It is commonly used in the transport of food, pharmaceuticals and other temperature-sensitive products to maintain their freshness and quality.

Guchen Thermo’s Recommendation Based on Models

◆ Short distance transportation: for small to medium refrigerated trucks, Guchen Thermo suggests TR series truck freezer, and C series chiller units. Our TR series and C series units are vehicle engine driven refrigeration systems.

--TR Models are truck freezer units (TR-200, TR-300, TR-450, TR-550 etc.). For truck freezer unit, its refrigerant is R404a, temperature can be range from -30℃ to +30℃ for delivering frozen or deep frozen cargoes, such as ice cream or frozen meat; A freezer unit can also be operated as a chiller if needed.

--C Models are chiller systems for fresh cargo delivery (C-200, C-300). For truck chiller units, its refrigerant is R134a, temperature range is from -5℃ to 25℃ for delivering fresh chilled cargoes, such as dairy product, fruits or vegetables.

◆ Long distance transportation: for big refrigerated trucks/trailers, we strongly recommend TS series engine driven refrigeration systems for a better, safe and effective cargo transportation.

Guchen Thermo cost effective TS series refrigeration units are diesel engine driven truck system whose cooling system rely on not vehicle engine but auxiliary diesel engine, more powerful and efficient. The self-powered diesel truck freezer units, also called as “independent truck refrigeration units”, are the best solution for transport companies operating larger rigid trucks.

Guchen Thermo designed the powerful TS Model to apply on 25~65 m³ truck box, and to deliver exceptional performance.

What are the Different Types of Truck Refrigeration Units?

Direct Drive Units: These units are powered by the truck's engine itself. They provide refrigeration using a belt-driven compressor attached to the truck's engine. Direct drives are simple and cost-effective, but they require the truck's engine to run for the refrigeration system to work.

Independent unit: Independent refrigeration unit with its own independent power supply or diesel drive unit. Self-contained refrigeration units offer greater flexibility as they can run even with the truck's engine off, allowing it to be parked for long periods of time or run overnight.

Hybrid Units: Hybrid refrigeration units combine electric and diesel power sources. They can switch between electric and diesel power when connected to an external power source, such as at a loading dock. This improves energy efficiency and reduces emissions, especially in urban areas where restrictions may be imposed on diesel engine operation.

Each type of truck refrigeration unit has its own advantages and is suitable for specific transportation scenarios. The choice of refrigeration unit depends on factors such as cargo type, distance traveled, dwell time, energy efficiency requirements, and local regulations.

Which Units Guchen Thermo would Recommend for Refrigerating Your Truck?

1. For Small Refrigerated Trucks (truck body sizes from 2m³ to 20m³ or length is < 3 meter)

------------

| Model |

TR-200 for pickup trucks |

| Driven Type |

Vehicle powered freezer unit |

| Mounting Type |

Front split mount system |

| Refrigerant |

R404a environment-friendly refrigerant |

| Range of Temperature Control |

from -25℃ to +30℃ to deliver chilled or deep frozen cargoes |

| Application |

For 6~15m³ truck body, small refrigerated trucks |

| No. of Condenser Fan |

1 |

| No. of Evaporator Fan |

1 |

|

|

|

|

------------

| Model |

TR-300 |

| Driven Type |

Vehicle powered truck freezer unit |

| Mounting Type |

Front split mount system |

| Refrigerant |

R404a refrigerant |

| Range of Temperature Control |

from -25℃ to +30℃ to deliver chilled or deep frozen cargoes |

| Application |

Apply for 10~20m³ small truck body box |

| No. of Condenser Fan |

1 |

| No. of Evaporator Fan |

2 |

|

|

|

|

------------

| Model |

C-200 |

| Driven Type |

Vehicle engine direct driven |

| Mounting Type |

Split nose-mount (front-mount) system |

| Refrigerant |

R134a |

| Range of Temperature Control |

from -5℃ to +30℃ |

| Application |

For container volume 2~10m³ truck body |

| No. of Condenser Fan |

1 |

| No. of Evaporator Fan |

1 |

|

|

|

|

------------

| Model |

C-300 |

| Driven Type |

Vehicle powered truck chiller |

| Mounting Type |

Split front-mount system |

| Refrigerant |

R134a |

| Range of Temperature Control |

from -5℃ to +30℃, perishable goods transportation |

| Application |

For container volume 10~15m³ truck body |

| No. of Condenser Fan |

1 |

| No. of Evaporator Fan |

2 |

|

|

|

|

Guchen Thermo small truck refrigeration units will never let you down and consistently offer superb performance.

2. For Medium Refrigerated Truck (truck body size is 15m³- 35m³ or length is <6 meter)

| |

|

|

|

| Model |

TR-350 |

TR-450 |

TR-550 |

| Application |

for 15~25m³ truck body |

16~25m³ |

25~35m³ |

| Driven Type |

Vehicle engine direct drive |

| Refrigerant |

R404a refrigerant |

| Temperature range |

-25℃ to +30℃

for storage/ distribution of chilled, frozen, deep-frozen food.

|

| No. of condenser fan |

1 |

2 |

2 |

| No. of evaporator fan |

1 |

2 |

3 |

| Mounting type |

Split front mount (nose-mounted) |

split front or under mounted |

| |

|

Tips: TR-350, TR-450, TR-550 models can apply for medium refrigerated trucks or big pickup truck. When the truck head is too high, customers can choose Guchen Thermo TR-550 under mounted truck freezer unit.

3. For Big Refrigerated Truck (truck body size is 35m³- 65m³ or length is <9 meter)

TR-650 model is the only one truck freezer unit suitable for big refrigerated vehicles among all Guchen Thermo’s TR series systems.It adopts R404a refrigerant, and temperature range is from -25℃ to +30℃. It is especially designed for areas with high heat/high ambient temperature (up to 50℃+), because its evaporator has 3 Italy Spal Fans, more powerful than other models.

TS model is Guchen Thermo’s diesel engine driven units, applies for medium to big refrigerated trucks. It adopts R404a refrigerant, and with independent refrigerating system, it not relies on the truck engine, so it is very suitable for long-distance transportation.

| Model |

Application |

Cooling capacity |

| TS-600 |

for 25-35m³ truck box |

5600W/19100Btu |

| TS-800 |

30-45m³ |

7150W/24400Btu |

| TS-1000 |

45~55m³ |

8250W/28150Btu |

| TS-1200 |

55-65m³ |

|

Guchen Thermo Novel TS Series truck freezer units are able to deliver higher airflow than the equivalent diesel units. They are more powerful, best for large refrigerated transport companies/fleets.

Guchen Thermo electric standby system includes TR-450S, TR-550S, and TR-760S model. The standby unit is installed in the inner side of condenser, super easy to install. Electric standby refrigeration system is dedicated designed to reduce diesel fuel consumption and emissions for fleets, to great extent, ensuring the cargoes safe on the road. They are with high quality, large cooling capacity.

Features:

Components of a Truck Refrigeration System

A truck refrigeration system consists of 8 key components that work together to provide cooling or refrigeration for the transported goods. The main components include:

Compressor: The compressor is responsible for compressing the refrigerant gas, raising its temperature and pressure. It is typically powered by a separate engine or motor.

Condenser: The condenser is a heat exchanger where the high-pressure and high-temperature refrigerant gas from the compressor releases heat and condenses into a liquid state. The condenser is usually located on the outside of the truck or trailer and uses either air or water to cool the refrigerant.

Expansion Valve or Orifice Tube: The expansion valve or orifice tube is a metering device that regulates the flow of refrigerant into the evaporator. It reduces the pressure and temperature of the refrigerant, allowing it to evaporate in the evaporator coils.

Evaporator: The evaporator is another heat exchanger typically located inside the cargo area of the truck or trailer. As the low-pressure and low-temperature refrigerant enters the evaporator, it absorbs heat from the air circulating over the evaporator coils. This cools down the air, which is then distributed back into the cargo area.

Refrigerant: The refrigerant is a specialized fluid that undergoes phase changes (from gas to liquid and vice versa) within the refrigeration system. It is responsible for transferring heat and enabling the cooling process.

Control System: The control system includes sensors, thermostats, and electronic controls that allow the operator to set and monitor the temperature inside the cargo area. The control system maintains the desired temperature by regulating the operation of the compressor, fans, and other components.

Fans: Fans are used to circulate air over the condenser and evaporator coils. They help in heat transfer and ensure efficient cooling throughout the system.

Power Source: The power source provides the necessary energy to operate the truck refrigeration unit. It can be a separate diesel engine, an electric motor, or a combination of both, depending on the type of unit.

These components work in a coordinated manner to remove heat from the cargo area and maintain the desired temperature, ensuring the freshness and quality of perishable goods during transportation.

How does a truck refrigeration unit work?

A truck refrigeration unit works by utilizing the principles of refrigeration to remove heat from the cargo area and maintain the desired temperature.

Compression: The process starts with the compressor, which is powered by a separate engine or motor. The compressor takes in low-pressure refrigerant gas and compresses it, increasing its temperature and pressure.

Condensation: The high-pressure and high-temperature refrigerant gas then flows into the condenser, which is usually located on the exterior of the truck or trailer. In the condenser, the refrigerant releases heat to the surrounding environment, usually through air or water cooling. As a result, the refrigerant undergoes a phase change and condenses into a high-pressure liquid.

Expansion: From the condenser, the high-pressure liquid refrigerant passes through an expansion valve or orifice tube. These devices act as throttling devices, reducing the pressure and temperature of the refrigerant.

Evaporation: The now low-pressure and low-temperature refrigerant enters the evaporator, which is typically situated inside the cargo area. As air from the cargo area passes over the evaporator coils, the refrigerant absorbs heat from the air, causing the refrigerant to evaporate. This evaporation process cools down the air circulating in the cargo area.

Circulation: Fans or blowers circulate the cooled air from the evaporator back into the cargo area, maintaining the desired temperature. The fans also help distribute the cool air evenly throughout the cargo area.

Refrigerant Cycle: The refrigerant, in its gaseous state after absorbing heat in the evaporator, returns to the compressor to restart the cycle. It is then compressed again, initiating another round of heat absorption, condensation, expansion, and evaporation.

Control and Monitoring: The truck refrigeration unit is equipped with a control system that allows the operator to set and monitor the desired temperature inside the cargo area. The control system regulates the operation of the compressor, fans, and other components to maintain the set temperature.

By continuously cycling refrigerant through the compressor, condenser, expansion valve, and evaporator, the truck refrigeration unit effectively removes heat from the cargo area, ensuring the preservation of perishable goods during transportation.

What type of refrigerant do truck refrigeration units use?

Truck refrigeration units typically use a variety of refrigerants, but the choice of refrigerant depends on several factors including the specific unit model, regulations, environmental considerations, and efficiency requirements.

R-134a: R-134a is a hydrofluorocarbon (HFC) refrigerant that has been widely used in truck refrigeration systems. It has low ozone depletion potential (ODP) but is considered a high global warming potential (GWP) refrigerant. R-134a has good thermodynamic properties and is compatible with many existing systems.

R-404A: R-404A is a hydrofluorocarbon blend commonly used as a replacement for older refrigerants, such as R-22 and R-502. It is a non-ozone-depleting refrigerant but has a high GWP. R-404A is known for its efficiency and is commonly used in truck refrigeration systems for both cooling and freezing applications.

R-407C: R-407C is another hydrofluorocarbon blend used in truck refrigeration units. It is a non-ozone-depleting refrigerant with a moderate GWP. R-407C offers similar performance characteristics to R-22 but is more environmentally friendly.

R-410A: R-410A is a hydrofluorocarbon refrigerant commonly used in air conditioning and heat pump systems. It has become popular due to its high energy efficiency and low impact on the ozone layer. While it is less commonly used in truck refrigeration units, it may be employed in certain specialized systems.

R-452A (Opteon™ XP44): R-452A, sold under the brand name Opteon™ XP44, is a hydrofluoroolefin (HFO) refrigerant designed as a low-GWP alternative to R-404A. It offers similar performance and efficiency but with a significantly lower GWP. R-452A is gaining acceptance as a more environmentally friendly option in truck refrigeration applications.

Guchen pays attention to the concept of environmental protection and sustainable development, and provides users with the choice of two refrigerants, R134A and R404A, and chooses the refrigerant according to your specific needs. It is worth noting that the field of refrigerants is constantly evolving due to environmental concerns and regulations. With the advent of newer refrigerants with lower GWP and improved environmental profile, R404A refrigerant is now becoming more common in truck refrigeration systems.

Features of Guchen Thermo Quality Transport Refrigeration Unit

1. Adopts hydrophilic aluminum foil with internal ridge copper tube in evaporator

We all know that copper has the high quality of anti-corrosion, better heat transmission, so adopts copper tube as the refrigerant line in HVAC systems can be prolonged the product service life a lot. Besides that, the hydrophilic aluminum foil materials will not make the water gather together and block tube, and it can improve heat exchange rate by 30%, which improve the refrigerating effect a lot.

2. Adopts aluminum micro-channel parallel flow coils in condenser

In the condenser, we adopt micro-channel parallel flow coils; it has the advantages of smaller in size, lighter in weight and compact in structure, so it is commonly used for HVAC systems. Employ parallel flow structure, the refrigerant can flow evenly, if refrigerant cannot flow evenly, it will compact evaporator’s heat exchange, which can lead to the refrigerating effect bad. So adopts aluminum micro-channel parallel flow coils in condenser also can improve the evaporator heat exchange rate and give a better cooling performance.

3. Add another heat exchange device in Evaporator

In order to increase the heat exchange and improve cooling effect, we add a heat exchange device in evaporator, so the heat exchange rate can be increased by 20%.

4. Adopts worldwide famous brands spare parts

The spare parts take a very important role in the whole refrigeration units, so Guchen Thermo always pay more attention on the spare parts, even the mini parts, we also choose the best quality for customers. The main spare parts include in:

◆ QP compressor from TCCI: High quality and easy to maintain

◆ Spal Fans: 10000-20000 hours service life, high quality.

◆ Danfoss filter drier, expansion valve, receiver and visual liquid length: Famous brands, easy to maintain, stable performance.

◆ Castel solenoid valve: Imported from Italy, has a high quality.

◆ Codan Pipeline: High quality and easy to maintain

5. Adding 2 valves: CPR valve and liquid injection valve

In the very hot areas, if compressors work some time, its ambient temperature will be high, so adding CPR valve and liquid injection valve can help to switch the compressor temperature, and protect compressor from broken, prolong the units’ service life.

6. Equip with standby system according to demands

All of Guchen Thermo refrigeration units can equip with standby system according to customers’ demands. Standby system is very helpful if transporters need to deliver cargoes from day to night, when at night, transporters only need to turn on standby system to refrigerate cargoes continuously. So it really help to save a lot of fuel and transportation cost.

7. Equip with heating system according to demands

For some very cold places, if the ambient temperature is below to -5℃ in winter, it is very necessary to install heating system, For example, when transport fresh cargoes, such as flowers, dairy products, fruits and vegetables etc. at very low temperature, increase the temperature above 0℃ can keep cargoes safe and fresh.

.jpg)